Automated label printing and application

Printing and applying labels automatically during production is a good solution when you want to avoid unnecessary steps. With automated application solutions, product labelling can be done efficiently, consistently and accurately. Automation frees up time and resources for other tasks in production, which also means that payback periods for solutions are typically very short. There are various labelling equipment and application methods available, and the specific requirements of the product and line should always be considered when choosing your solution.

The application equipment must be suitable for the production or packaging line in terms of capacity and usability. Applicators increasingly come with verifiers that can check the quality of barcodes, text readability and accuracy of the content, as well as the positioning and adhesion of the label.

Labelling methods include feeding the label directly onto the passing product, tamp application, as well as wipe and blow application, among others. Labelling is possible on all sides of the product: on the bottom, wrapped around the corner, etc. The techniques used for pallet labelling are primarily the same, but compared to the equipment used for labelling products and groups of products, certain specific features are required of pallet labelling equipment, such as larger label sizes and longer reach of the applicator.

Explore our top products

cab HERMES Q

State-of-the-art printing and application system!

cab HERMES Q ensures fast and accurate labelling of any product. The cab HERMES Q machines are designed to meet even the most demanding needs. The machines allow you to automatically and reliably print and apply labels onto packaging and products of all sizes. HERMES Q offers excellent print and application quality regardless of label size, shape or material.

Speed and efficiency are among the main advantages of HERMES Q. Thanks to the machines’ high performance, you can process large quantities of products within a short time, making production more efficient and saving valuable time. The integrated sensor technology of the machines automatically detects the position of the labels and applies them precisely to the right place. This reduces errors and increases productivity.

cab HERMES Q will streamline your production process, improve your brand visibility and help you achieve better results.

Novexx XLS 2XX

A convenient labelling head for various needs!

The labelling head is designed for printing on a wide range of printing needs and various products and surfaces. Suitable for both narrow and wide labels. Very durable thanks to its high-quality components. Its compact design makes it ideal for a wide range of production lines. The labelling head automatically adapts to the conveyor belt’s speed and can be combined with a wide range of applicators.

Novexx XPA 93X Print & Apply

The leading print and apply solution!

This machine meets even the most demanding production needs. Whether you have a small business or large factory, the XPA-93x series offers efficiency, accuracy and flexibility in the product labelling process. The machine combines cutting-edge printing technology and automatic label application in one compact and easy-to-use package. You can print high-quality, clear labels for a variety of purposes, including product packaging, logistics and warehousing. The speed and accuracy of the machine ensure your production line runs smoothly without delays and interruptions. You can be confident that each label is applied to the right place at the right time. The machine’s versatile application methods also allow you to choose the optimal solution for your products and production process.

The XPA-93x is designed to make your work easier and free up your resources. The system’s user interface and easy-to-use software enable quick deployment and effortless operation.

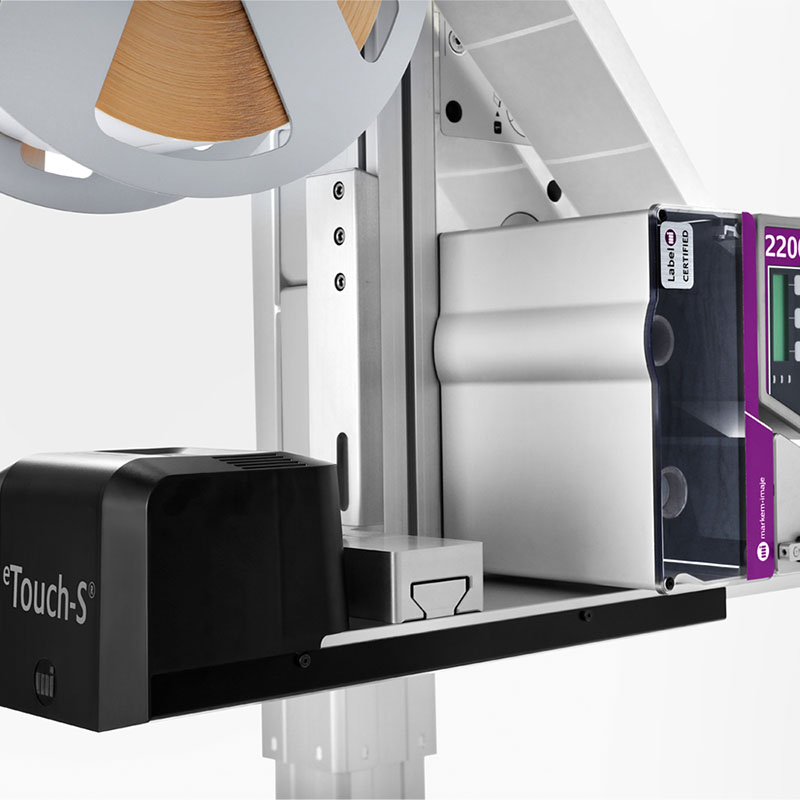

Markem-Imaje eTouch-S

A winning labelling system!

Markem-Imaje’s new eTouch-S won the PPMA Award for Innovative Packaging Machinery last year. The award recognises the best innovations in the packaging industry.

eTouch-S is a print and apply labelling system that has been designed in response to customer needs to reduce the environmental impact of labelling and improve occupational safety. It makes the label application process easier. The system’s easy-to-use touch screen interface makes operation quick and effortless. You can easily adjust and manage the applicator’s functions, saving time and reducing human error.

The applicator’s accuracy is second to none. It ensures that each label is applied precisely to the desired location. Thanks to its fast operation, you can apply a large number of labels in a short time, making production more efficient.

The most common way to apply a label is by touch. It is a good solution for most production lines and packaging needs. Blow is a non-contact application method that works best for fragile, soft and curved packages, and the combined touch-blow method is ideal for uneven surfaces. The advantage of the wipe method is that the label can be applied to the approaching end and/or side of the package with the same machine.

eTouch-S is particularly well-suited for delicate, soft and curved packages and products.

Markem-Imaje 2200

Efficiency and accuracy are key!

Markem-Imaje 2200 applicators have been developed to meet demanding industrial needs. Versatility is one of the key features of the 2200 applicators. The machines can print on a variety of surfaces, including cardboard, plastic, glass and metal.

They also offer excellent print speed and accuracy, which is particularly important for high production volumes. The Markem-Imaje 2200 machines also feature easy-to-use control panels and user interface, making it effortless to use and allowing for quick deployment. The printer also comes with advanced features, such as remote monitoring and maintenance to ensure efficient operation and minimise potential production downtime.

More information:

Petteri Mäkelä

Key Account Manager

Forest products industry, construction industry, metal industry, plastic and rubber industries, chemical industry, manufacturing of electrical equipment

+358 207 208 222

petteri.makela@informa.fi

Jari Kyllönen

Key Account Manager

Forest products industry and sawmills, pharmaceuticals and health technology, breweries and roasteries, printing industry and the logistics and wholesale

+358 207 208 243

jari.kyllonen@informa.fi

Jaakko Ahtila

Key Account Manager

Food, electronics, cable and pipe industries and fisheries

+358 207 208 266

jaakko.ahtila@informa.fi

Timo Tornberg

Key Account Manager

Food and beverage industries, textile industry

+358 207 208 262

timo.tornberg@informa.fi